- 1. Food processing industry

- 2. Catering service industry

- 3. Family and Retail

- 4. Industrial and Special Purpose

.webp?x-oss-process=image/resize)

Language

Application Scenarios For Egg Liquid Processing Line

Jun 11, 2025

Egg liquid (including whole egg liquid, egg white liquid, egg yolk liquid, and seasoning egg liquid) is widely used in the following fields due to its convenience, safety, and standardization characteristics

.jpg)

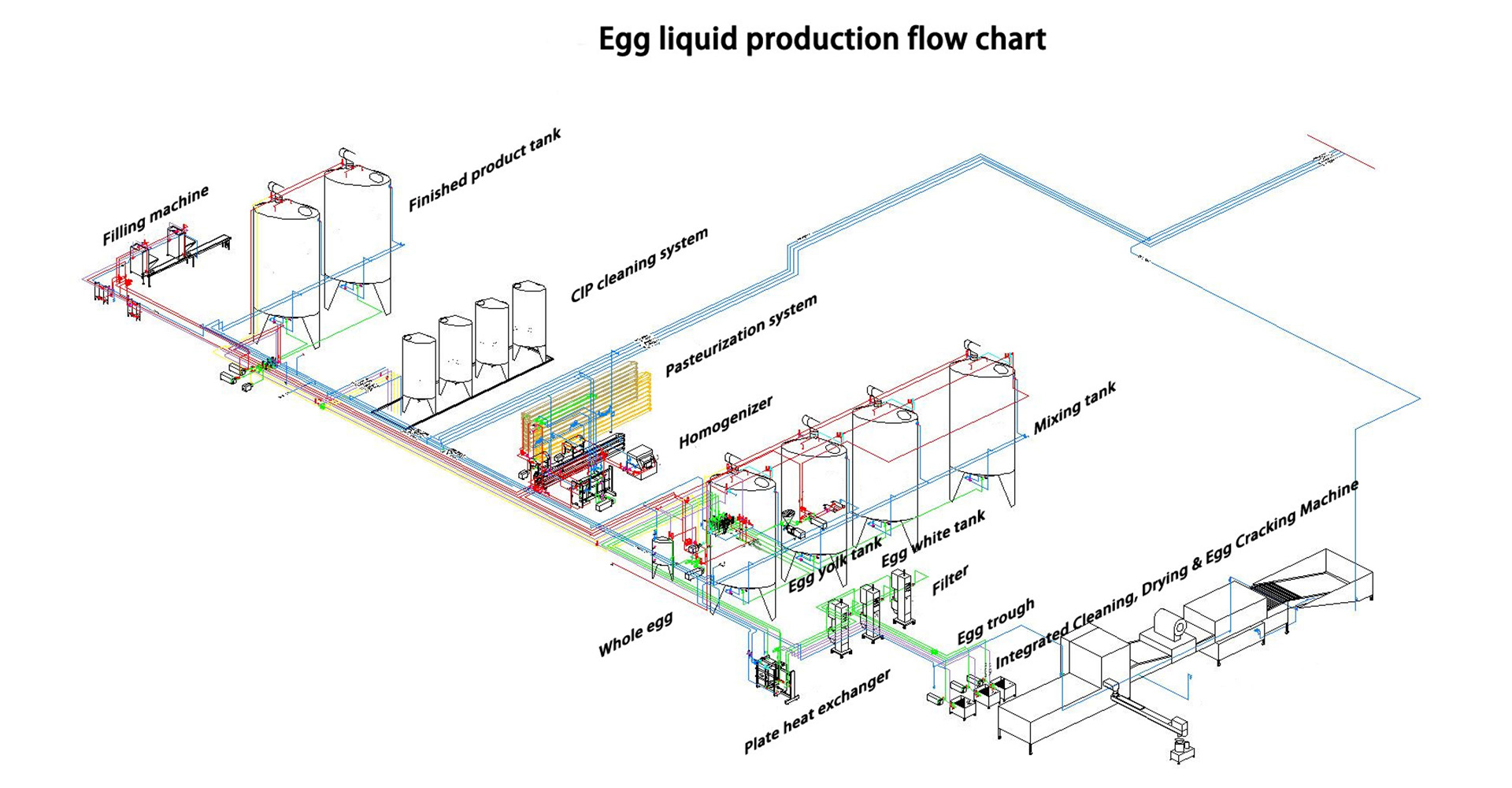

Egg production equipment covers the entire process from raw material processing to finished product packaging, with main application scenarios including:

1. Egg processing plant

Cleaning and sorting equipment: Remove eggshell dirt and sort cracked eggs (such as optical detectors and ultrasonic cleaning machines).

Egg beating and separation equipment: The fully automatic egg beating machine separates egg liquid and eggshell, and the egg yolk and egg white separator meets the needs of different products.

Sterilization equipment: Pasteurizer or High Temperature Transient Sterilization (HTST) ensures food safety.

Homogenization and filtration equipment: eliminates egg layering and improves texture uniformity.

Filling and packaging line: sterile filling machine, vacuum packaging machine to extend shelf life, supporting liquid or frozen egg liquid packaging.

1. Egg processing plant

Cleaning and sorting equipment: Remove eggshell dirt and sort cracked eggs (such as optical detectors and ultrasonic cleaning machines).

Egg beating and separation equipment: The fully automatic egg beating machine separates egg liquid and eggshell, and the egg yolk and egg white separator meets the needs of different products.

Sterilization equipment: Pasteurizer or High Temperature Transient Sterilization (HTST) ensures food safety.

Homogenization and filtration equipment: eliminates egg layering and improves texture uniformity.

Filling and packaging line: sterile filling machine, vacuum packaging machine to extend shelf life, supporting liquid or frozen egg liquid packaging.

-

CIP Cleaning

-

Storage after slaughter

-

Pasteurization and canning

-

Pasteurization machine

-

Beat eggs, store and filter

-

Pasteurize egg liquid

-

Store egg liquid

-

Egg water tank

2. Supporting production lines for food enterprises

Baking/Meat Products Factory: Integrated egg liquid processing equipment, directly supplying production line needs.

Central kitchen: Small and medium-sized egg beaters and sterilization equipment meet the needs of batch pretreatment.

Baking/Meat Products Factory: Integrated egg liquid processing equipment, directly supplying production line needs.

Central kitchen: Small and medium-sized egg beaters and sterilization equipment meet the needs of batch pretreatment.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Jun 11, 2025

Application Scenarios of Ice Cream Production Line

.jpg?x-oss-process=image/resize)